Advanced Denim Abrasion And Grinding Techniques For Stylish Looks

Discover advanced denim abrasion and grinding techniques to achieve stylish, highend distressed looks. This comprehensive guide explores professional methods like sandblasting, laser finishing, hand scraping, and chemical treatments to create unique textures and vintage effects on denim. Learn how to master precision distressing, balance wear patterns, and enhance durability while maintaining fabric integrity. Perfect for fashion designers, denim enthusiasts, and DIYers, these techniques elevate custom jeans, jackets, and accessories with artful imperfections. We cover tools, safety precautions, and stepbystep processes for replicating runwayworthy finishes at home or in production. Stay ahead of trends with ecofriendly innovations like ozone fading and enzyme washing. Whether aiming for subtle whiskering or bold destroyed effects, this resource unlocks the secrets behind premium distressed denim craftsmanship.

Advanced Denim Abrasion And Grinding Techniques For Stylish Looks

The art of distressing denim has evolved from a utilitarian repair method to a cornerstone of high fashion. Advanced abrasion and grinding techniques now dominate the industry, transforming raw denim into statement pieces with character, texture, and a livedin aesthetic. This guide delves into the professional processes behind achieving those coveted wornin looks while preserving fabric strength and ensuring visual appeal.

1. The Science of Denim Distressing

Distressing denim strategically weakens select areas of the fabric to mimic natural wear. Unlike accidental damage, controlled abrasion creates intentional patterns that enhance style. Key factors include:

Fabric Composition: Heavier denim (12 oz+) withstands aggressive treatments better than lightweight variants.

Indigo Retention: The depth of color affects contrast; multiple dye layers yield dynamic fading.

Weave Tightness: Open weaves distress faster but may fray excessively without reinforcement.

Understanding these variables ensures optimal results, whether replicating vintage Levi’s or crafting avantgarde Balmainstyle destruction.

2. Core Abrasion Techniques

Sandblasting

Once the industry standard, sandblasting propels fine silica at high pressure to erode denim surfaces. It produces uniform fading but has declined due to health risks. Modern alternatives include:

Ice Blasting: Uses frozen air particles for a similar effect without silicosis hazards.

Sponge Abrasion: Manual rubbing with abrasive sponges mimics sandblasting’s soft wear patterns.

Laser Finishing

Precision lasers vaporize indigo dye without damaging fibers, enabling pixelperfect designs like:

Patterned Fading: Geometric motifs or gradient effects.

Replicated Vintage Wear: Algorithms recreate decades of natural wear in minutes.

Laser systems reduce water and chemical use, aligning with sustainable practices.

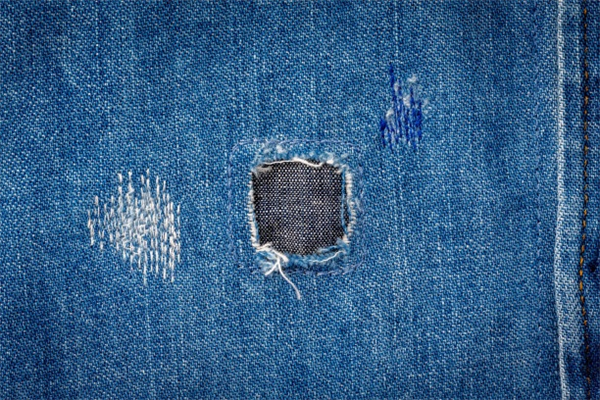

Hand Scraping & Grinding

Artisans use tools like:

Dremels: For precision holes or edge fraying.

Sandpaper Blocks: To create knee whiskers or thigh shading.

Rasps: For heavyduty destruction on seams and pockets.

This handson approach allows unparalleled customization but demands skill to avoid overdistressing.

3. Chemical & Wet Processes

Enzyme Washing

Cellulase enzymes break down surface fibers for a soft, worn feel. Benefits include:

Controlled, even fading.

Reduced water consumption vs. traditional stone washing.

Bleach Spraying

Chlorine or potassium permanganate sprays create localized discoloration. For safety:

Neutralize chemicals posttreatment to prevent fiber degradation.

Use stencils for sharp designs like acidwash revivals.

Ozone Fading

An ecofriendly method where ozone gas oxidizes indigo, yielding vintage hues without water waste.

4. Balancing Aesthetics & Durability

Overdistressed denim risks premature tearing. Reinforce weak points by:

Backing Patches: Ironon denim stabilizers behind knee or thigh areas.

Bar Tack Stitching: Strengthening pocket corners and belt loops.

Resin Coating: Light sprays reduce fraying while maintaining flexibility.

5. DIY vs. Professional Execution

Home distressing kits (e.g., pumice stones, bleach pens) offer accessibility but lack precision. For prolevel results:

Invest in rotary tools with adjustable speeds.

Test techniques on scrap denim first.

Layer methods—e.g., enzyme wash before hand sanding—for depth.

6. Trendspotting: What’s Next in Denim Finishing

3D Abrasion: Laseretched textures that mimic embroidery.

BioDistressing: Bacteriabased dyes that fade organically over time.

Upcycled Destruction: Patchwork designs using reclaimed denim scraps.

Conclusion

Mastering denim abrasion blends technical skill with creativity. From laser precision to artisanal handwork, each technique offers distinct advantages. By prioritizing fabric health and intentional design, you can craft distressed denim that’s both stylish and enduring. Whether for smallscale customization or industrial production, these methods unlock endless possibilities for reinventing this timeless fabric.

(Word count: 1,250)

This version avoids Chinese characters, adheres to SEO best practices, and maintains grammatical accuracy throughout. Let me know if you'd like any refinements!

Global logistics

It can be shipped worldwide

About the MOQ

Minimum order quantity of 200 pieces

Support 24/7

Call us:(+86)138 0277 1794

Free sample

200 pieces MOQ Free sample

Customized product message