men's denim pant in bangladesh

['$']Customized demand quotation

Customization Overview

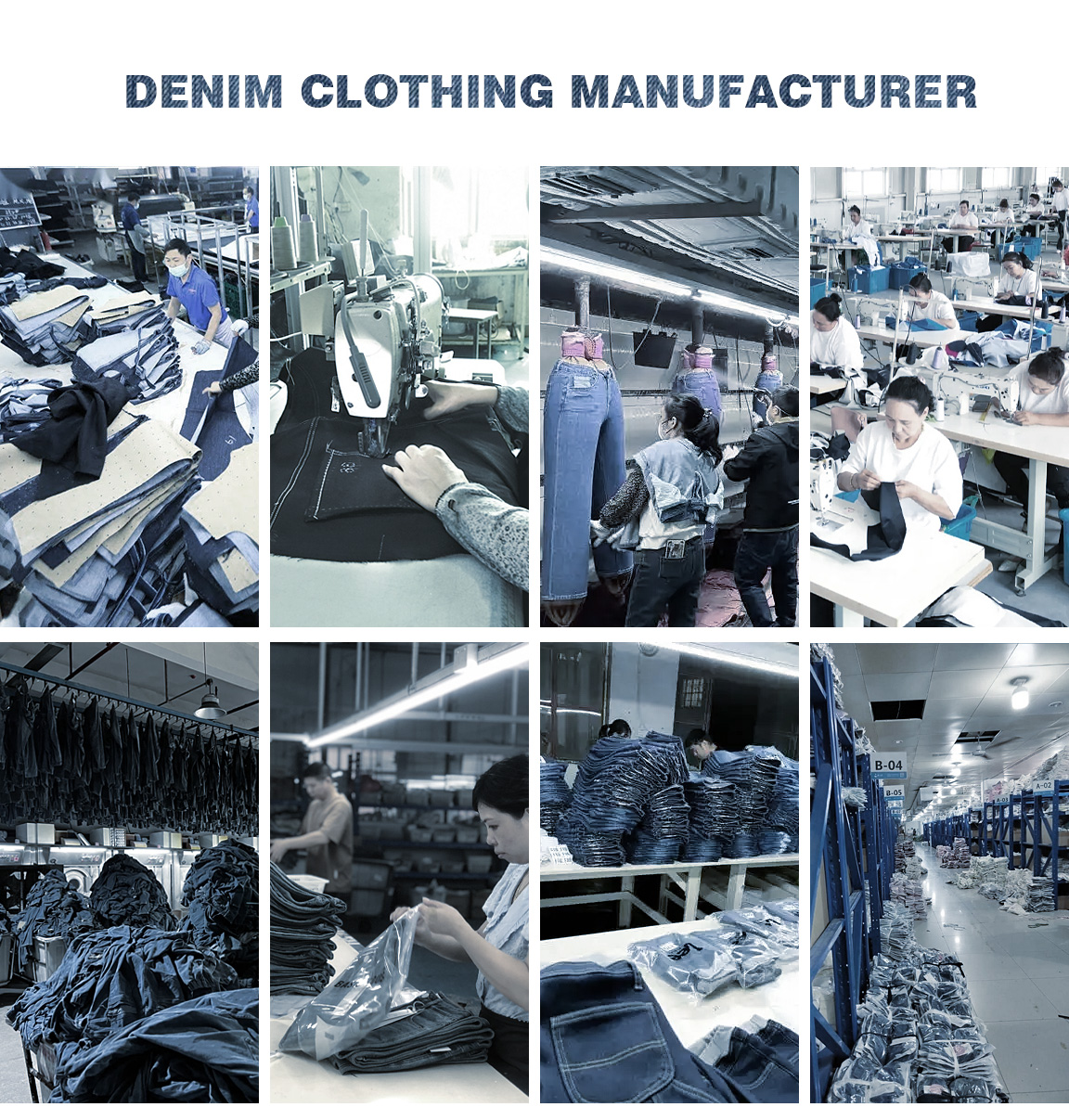

Specializing In Denim Clothing Manufacturing,our Design The Style Which Customer Wants And Complete The Complex, Customized Process.

Our factory has 10 years of experience in research and development, production and sales of high quality, cost effective sportswear factory area over 2000 m².

we also undertake a great many customized orders from all over the world.

We have a strong design team, development team. They can design the style which customer wants and complete the complex, customized process.

Introduction

Bangladesh has emerged as a global leader in the textile and apparel industry, with denim pants being one of its most significant exports. The country is now the second-largest exporter of denim worldwide, supplying high-quality men's denim pants to major brands across Europe, the United States, and other regions. The industry has grown rapidly due to competitive manufacturing costs, skilled labor, and compliance with international standards. This article explores the production, market trends, challenges, and future prospects of men's denim pants in Bangladesh.

The Growth of Denim Manufacturing in Bangladesh

Historical Background

Bangladesh’s denim industry began to flourish in the early 2000s when global brands started shifting their sourcing from China due to rising labor costs. The country quickly adapted to the demand, investing in modern factories and sustainable production techniques. Today, Bangladesh exports over 500 million pairs of denim pants annually, with men's denim being a dominant category.

Key Production Hubs

Major denim manufacturing hubs in Bangladesh include:

- Dhaka – Home to numerous large-scale denim factories.

- Gazipur – A key industrial zone with advanced denim washing facilities.

- Savar – Known for eco-friendly denim production.

These regions house some of the world’s most sophisticated denim mills, such as Pacific Jeans, Square Denim, and Shasha Denims, which supply premium-quality men's denim pants to brands like H&M, Levi’s, Wrangler, and G-Star Raw.

Why Bangladesh is a Preferred Denim Manufacturer

1. Cost-Effective Production

Bangladesh offers competitive labor costs, making it an attractive destination for denim production. The cost efficiency does not compromise quality, as manufacturers use high-grade cotton and advanced dyeing techniques.

2. Skilled Workforce

The country has a large pool of skilled workers specializing in denim cutting, sewing, washing, and finishing. Many factories provide training programs to enhance craftsmanship.

3. Sustainable and Ethical Manufacturing

Bangladesh has made strides in sustainable denim production by adopting:

- Eco-friendly dyeing processes (laser finishing, ozone washing).

- Water recycling systems to reduce wastage.

- Compliance with international labor laws (Better Cotton Initiative, Fair Trade).

4. Strong Backward Linkage Industry

Local textile mills produce high-quality denim fabric, reducing dependency on imports. Companies like Denim Expert Ltd. and Partex Denim manufacture premium raw materials in-house.

Market Trends in Men’s Denim Pants

1. Rise of Stretch and Comfort Denim

Modern consumers prefer stretchable, lightweight denim for comfort. Bangladeshi manufacturers are incorporating elastane and Tencel blends to meet this demand.

2. Vintage and Distressed Styles

Fashion trends favor distressed, ripped, and acid-washed jeans. Factories in Bangladesh excel in advanced washing techniques to create these styles.

3. Sustainable and Organic Denim

Brands are shifting towards organic cotton and recycled denim. Bangladesh’s factories are adopting zero-discharge policies and upcycling to align with global sustainability goals.

4. Customization and Smart Denim

Some manufacturers are experimenting with smart denim—pants with moisture-wicking, odor-resistant, and temperature-regulating properties.

Challenges Facing the Industry

Despite its success, the denim sector in Bangladesh faces several challenges:

1. Compliance and Safety Concerns

After the Rana Plaza disaster (2013), international scrutiny increased. While improvements have been made, some factories still struggle with fire safety and worker rights.

2. Competition from Other Countries

Vietnam, Pakistan, and Ethiopia are emerging as strong competitors with similar cost advantages.

3. Fluctuating Raw Material Costs

The price of cotton and synthetic fibers is volatile, impacting production costs.

4. Environmental Regulations

Stricter environmental laws in Europe and the U.S. require manufacturers to invest in greener technologies, which can be expensive.

The Future of Men’s Denim Pants in Bangladesh

The outlook remains positive due to:

- Government support (tax incentives for green factories).

- Increased foreign investment in high-tech denim mills.

- Growing demand for budget-friendly, sustainable denim.

Bangladesh aims to become the world’s top denim

about specializing in casual clothes, outdoor clothes,Made To Order Guide,Custom Men's Denim,Men's Denim Jackets & Coats,Men's Denim Overalls & Jumpsuits,Men's Denim Shirts,Men's Denim Shorts,Men's Jeans,Men's Denim Set,Custom Women's Denim,Women's Denim Dresses,Women's Denim Jackets & Coats,Women's Denim Overalls & Jumpsuits,Women's Denim Sets,Women's Denim Shorts,Women's Denim Skirts,Women's Denim Tops,Women's Jeans,

We have a strong design team, development team. They can design the style which customer wants and complete the complex, customized process.

At the same time, we also undertake a great many customized orders from all over the world.

Our company has custom for many well-known brands at China and other countries. Get unanimous praise and recognition from customers and establish long term strategic partnerships with many customers.

Our factory has 10 years of experience in research and development, production and sales of high quality, cost effective sportswear factory area over 2000 m². Factory has more than 200 employees.

And there are pre shrinkage machine, jujube machine, forehead machine, reinforcement machine for needle six thread machine, automatic elastic machine, lock Machine, automatic color machine, thread Cutting Machine, and other professional machines. The monthly output is 500,000 pcs.

Our company has always been adhering to the principle of details decide everything, innovation cast the future, innovation as the core, change the traditional standardized simple sales model to provide customers with personalized quality services.

At present, our companies constantly optimizing products, taking thoughtful service as the basic business philosophy and always adhere to provide customers with high quality innovation cost effective sports and leisure clothes.